Tractive force, what is it? Its the amount of force available to the tires to use to push you and your car in the direction you desire. This can be used for acceleration in the forward, backward, side-to-side, or a combination of these directions. The more total tractive force your car has, the faster the car is able to change direction, which in-turn means the car is able to navigate it’s desired path faster. Getting through the course faster in most motorsports is a good thing because well… it’s a race to the finish line. This has become the case as well with competitive drifting too. Speed is one of the judged criteria in most competitive drift series. Having a fast car is also necessary to enable the following driver the means to stay close to the lead driver in tandem.

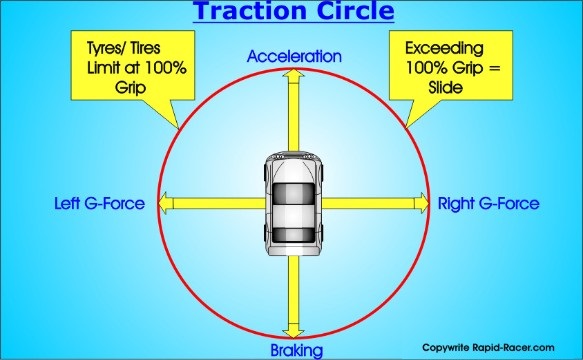

The traction circle is a good visualization of the tire having a finite amount of total tractive force it can produce.

The traction circle is a good visualization of the tire having a finite amount of total tractive force it can produce.

Having the most tractive force possible is desired for a competitive car. As drifters we want the most tractive force or “grip” we can get out of our cars, but we still need to be able to overcome that tractive force to keep the tires spinning to keep the car in drift. We also want our cars to be easy to drive so we are able to consistently maneuver the car and not straighten out when we have to change course due to unforeseen circumstances.

This is the part where some people will hate me because I’m not a purist. Most of the time a larger displacement motor will be better suited for drifting than a smaller displacement turbo motor. Why? because the larger displacement will generally produce its peak torque sooner in the power band while having a larger span in the rpm range that it produces these torque numbers. The tuner will be able to increase the amount of “grip” to the car has because the engine that produces more torque will be able to break the tires loose at higher “grip” levels.

V8 engine swaps such as the LSx series or V-Fusion (my favorite is Acai Mixed Berry) are common engine swaps in drift cars. Sometimes you will see more V8 engines than low displacement turbo engines in cars at a drift event.

V8 engine swaps such as the LSx series or V-Fusion (my favorite is Acai Mixed Berry) are common engine swaps in drift cars. Sometimes you will see more V8 engines than low displacement turbo engines in cars at a drift event.

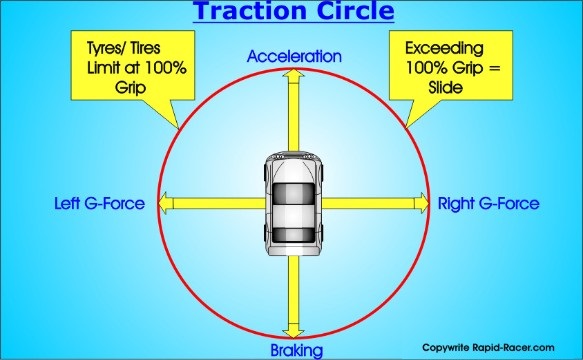

We look at the torque output of the engine because it’s a pretty good indication of how much force can be applied to the contact patch of the tire to aid in forward acceleration of the car (although you can gear a low torque high rpm engine to less overall rpm to produce a higher torque number). For example to accelerate a 3000lb car at 1g, you would need something to push the car forward with 3000lb of force. To achieve this an engine applies power to through the drive-train to rotate the wheels which then roll on the ground. The reaction force from the ground to the tires is what actually pushes the car forward.

Wait, how does torque relate to this force? Torque is in units like ft-lb and force is in units like lb. The force at the contact patch is acting at a distance (commonly known as a moment). This distance is drawn perpendicular to the force through to the center of the wheel (this end up being the radius of our tire). Lets assume the radius of the tire we are looking at is 12in which is conveniently 1ft. This means the drive train needs to produce 3000ft-lb of torque to accelerate our car at 1g (3000lb * 1ft = 3000ft-lb).

A quick free body diagram that gives an idea of how the torque from the engine accelerates a car.

A quick free body diagram that gives an idea of how the torque from the engine accelerates a car.

Woah, that seems unrealistic. There’s a solution to this problem, gearing. Lets say our total gear reduction ratio is 6, then we divide the 3000ft-lb requirement by 6 to get an engine output required to be 500ft-lb to accelerate us at 1g. This trade off is at the expense of overall rpm, now our wheel will spin at 6 times less rpm than the engine (Another way to think about this is comparing a large breaker bar and a small nut-driver. You can apply more torque with a breaker bar than with a nut-driver, but you can turn the nut-driver faster than the breaker bar). Tuning is all about trade-offs.

Having a wide torque band is a good thing. The wider the band of torque the engine produces, the wider range you have to use that torque. This means you can use more of the higher gear reduction ratios that produce more force at the tires, which allows you to accelerate at a higher rate for a longer period of time.

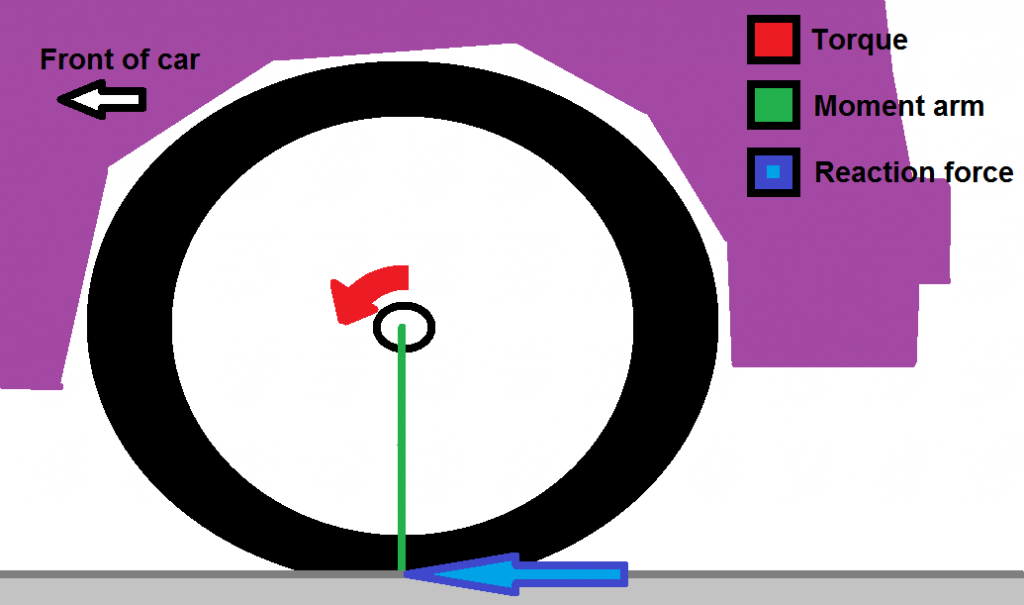

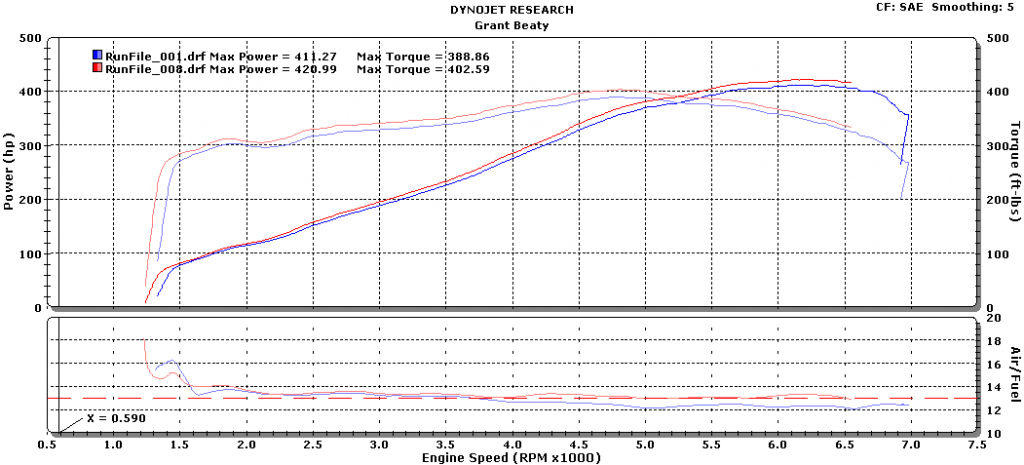

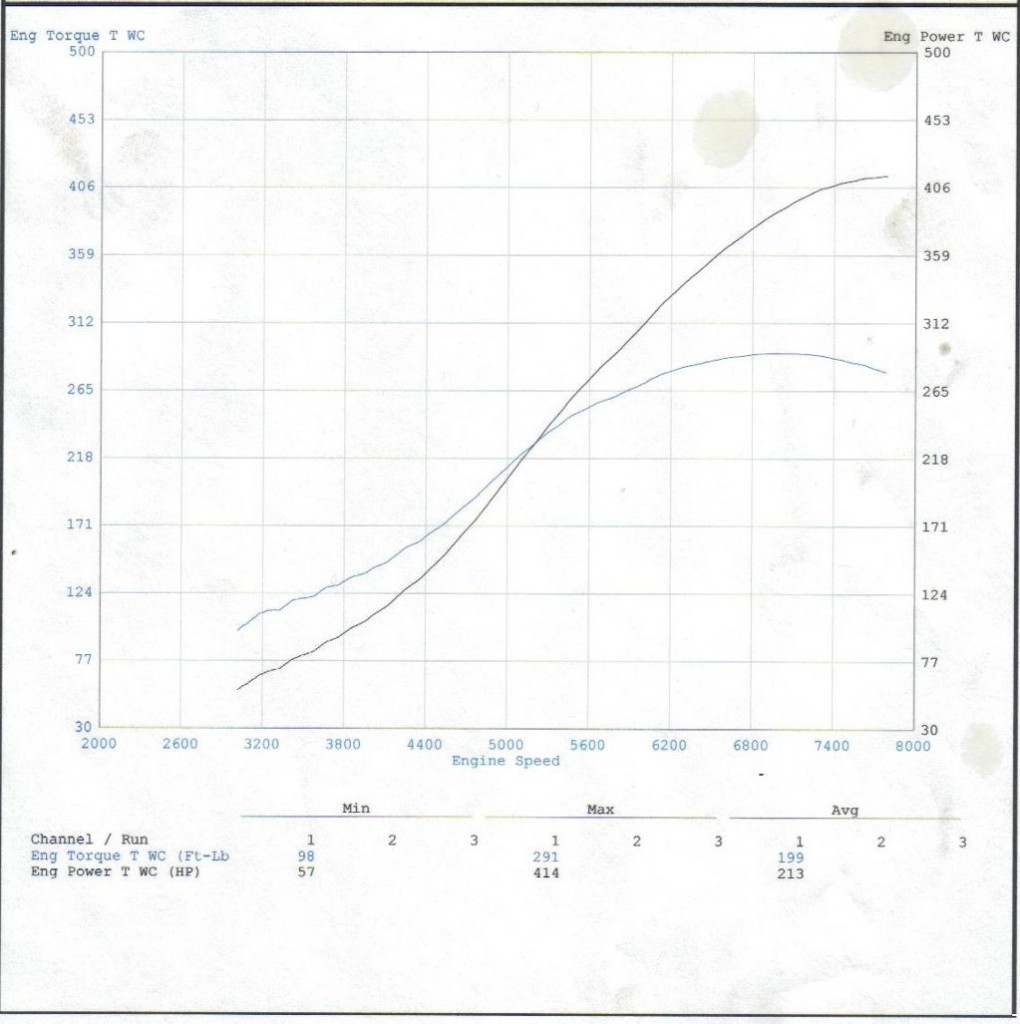

The following two images are dyno charts. One describes a ~420 hp LS1 while the other describes ~420 hp SR20. Let’s look at the LS1 chart first. The LS1 makes 300 ft-lb or torque right around 2000 rpm and then drops below 300 ft-lb of torque right around 6700 rpm. According to my calculations that’s 4700 rpm that the engine produces over 300 ft-lb of torque. On the other hand the SR20 starts producing 300 ft-lb of torque at around 4700 rpm due to turbo lag and stops producing over 300 ft-lb of torque around 7300 rpm. That’ a 2600 rpm range where the SR20 is producing over 300 ft-lb of torque. If you need to produce 300 ft-lb of torque from the engine to break loose the tires you have almost double the range of rpm to achieve this with the LS1 engine over the SR20. This wide range of rpm that the tires will break loose makes it much easier for the driver to keep the car drifting in unpredictable circumstances.

Dyno chart for an LS1 producing about 420 hp.

Dyno chart for an LS1 producing about 420 hp.

Dyno chart for a SR20 that produces a similar amount of power (416 hp).

Dyno chart for a SR20 that produces a similar amount of power (416 hp).

Another thing to note is that the static coefficient of friction is higher than the kinetic coefficient of friction. This means it takes less torque to keep the wheels spinning than it takes to start the wheels spinning. This also means that we only care about if our engine can produce enough torque to break the tires loose, and any torque higher than that doesn’t really matter. This is because the tire can only do so much when it is spinning. Applying more torque to the tire above the amount needed to keep it spinning doesn’t do much for us. The thing that matters most is the rpm range the engine can produce enough torque to break traction of the rear tires. If the engine’s torque is increased, more “grip” can be dialed in to match these higher torque numbers. The more “grip” is added the faster the car will drift.

The car will also be easier to drive (read: consistent) the longer the engine is able to provide breakaway torque to the tires. With a larger rpm range to work with, the driver is able to quickly and effortlessly initiate wheel spin in more situations than they would have with a lower range of rpm to work within.

Generally having an engine with a wide torque-band allows you to dial in your suspension to have more “grip” while still being able to control the car consistently. This goes to show that when thinking about handling characteristics of a drift car, there’s more to how a car feels than suspension setup. The car has many systems that have to work together to perform well.

-Mark