Testing is going great on Prototype v1.2 tension rods on both the s13 and s14. In the meantime I decided to try experimenting with electrical components for fun (which is sort of scary with my mechanical background).

I bought an accelerometer and a SD card adapter for less than $10 shipped to my door, wired them into an Arduino. I then wrote the program that records the analog accelerometer outputs to a .txt file on a micro SD card.

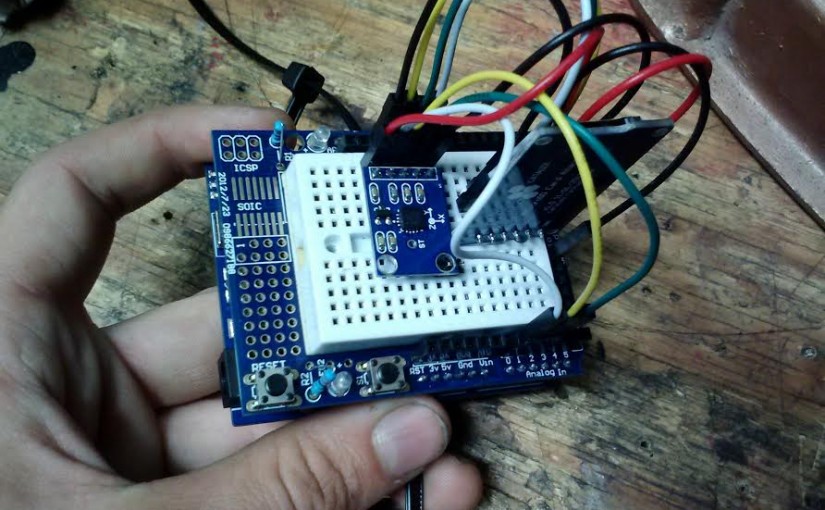

After all of that I am left with this:

The analog accelerometer can be seen in the center of the breadboard. The SD card adapter is the vertical chip to the right of the accelerometer.

I then mounted the assembly to the center of the car with a zip-tie and an adhesive backed zip-tie clip attached to the bottom of the Arduino board. Plug in a 9v battery and then comes the fun, I did some skids to record data.

Thanks to Trey Chavis for the Photo

Thanks to Trey Chavis for the Photo

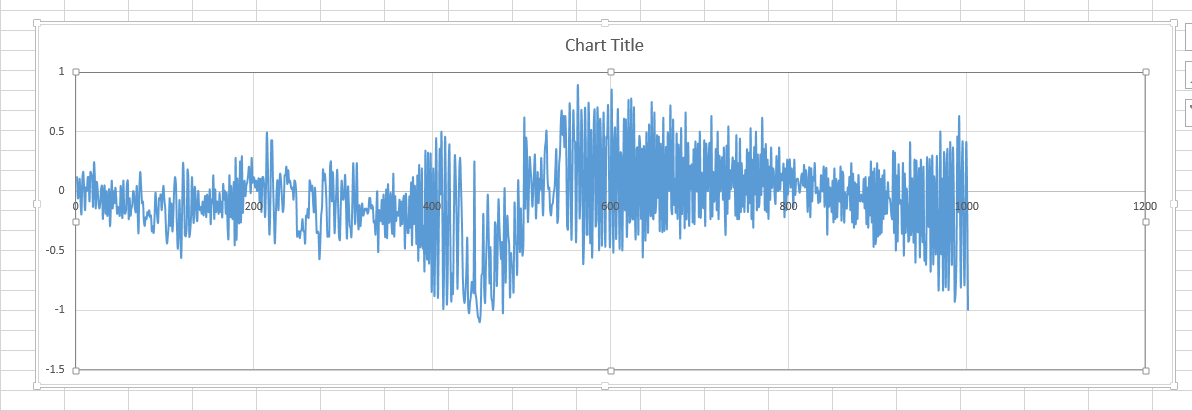

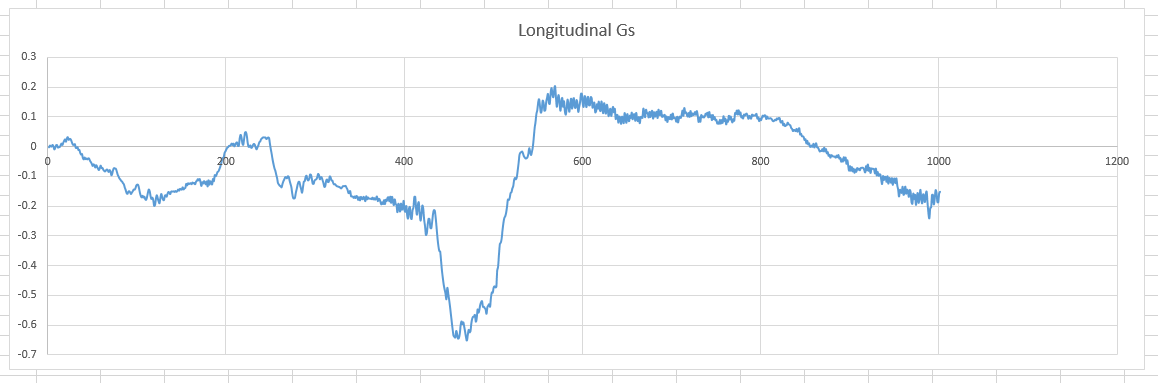

Once back home I opened the .txt file in excel and then plotted the data. The data is really noisy due to the accelerometer picking up all the vibrations from the engine. In raw form it looks like this (I cut down the data in this image because I recorded way too much):

The data can be smoothed with Excel and it then looks like this:

This bit of data is from acceleration in 2nd gear (with no tire spin). I picked it because it had the most area under the curve (looks nicer too) after smoothing.(I still have to figure out a better way to damp the Arduino when mounted to decrease noise)

This graph shows a max acceleration of 0.6 Gs which is about 19.32 ft/s^2

From the internet we can find the overall gear ratio of the drive-train which is 7.76 (sr20det 2nd gear = 1.902 , stock 240sx final drive ratio = 4.08).I’m using a 235/40/17 tire which has an overall diameter of about 24.4 in. = 2.03 ft.

The weight of the car is sort of a guess (I really need to get on a set of scales). But we will assume its a little heavier than stock because of the cage at 2900lb.

Pounds is a force and we know Force = Mass * Acceleration due to gravity so….

240sx mass = 2900 lb / 32.2 ft/s^2 = 90.06 slugs (don’t put salt on them)

With all this information and some maths we can find out how much torque and horsepower the engine had to output to achieve this acceleration. SCIENCE!

Engine torque = ((240sx mass * Acceleration Gs) * (Tire Diameter / 2)) / (Overall Gear Ratio)

= (90.06 slugs * 19.32 ft/s^2) * (2.03 ft / 2) / 7.76 = 227.6 ft*lb at the wheels.

Accounting for drive-train losses: crank torque = (227.6 ft*lb) / .75 = 303.4 ft*lb

(I don’t think my engine produces this much torque, so I think my assumptions may be a little off or the sensors need calibration, but it’s still good enough to do calculations).

I’m not sure what RPM I was at during this time but I’m going to guess 5000 rpm for the power calculation.

Power is in units of ft*lb/s or hp (550 ft*lb/s = 1 hp).

Power = (Torque * rpm) * (2pi) * (1m/60s) = (303.4ft*lb * 5000rpm) * (2pi) * (1m/60s) = 158779.3 ft*lb/s = 288.7 hp

The accelerometer can output data in the X, Y, and Z directions so data is logged in these directions too. I just used the longitudinal data to show how a quick calculation can provide some real world information. Another great application for this is to compare overall G information between car setups to find which setup provides the highest Gs which indicates more grip which indicates more speed (most of the time).

-Mark