3D printing has been around for a while, but within the past few years its popularity has really grown. 3D printers are capable of using durable materials like ABS, they have easy to use software, and consumer level costs to ownership. With these factors many engineering groups and hobbyists alike are using 3D printing to make functional prototypes and sometimes even final parts. 3D printing is capable of making parts with enough detail to hold a functional tolerance.

Here are some samples of what can be done with 3D printing. The knurled nut and bolt were both printed with just 0.3mm resolution (most FDM printers go down to about 0.1mm resolution in the z axis) and they look great. The flexible fish skeleton was made with just one print without any pieces fusing together.

Here are some samples of what can be done with 3D printing. The knurled nut and bolt were both printed with just 0.3mm resolution (most FDM printers go down to about 0.1mm resolution in the z axis) and they look great. The flexible fish skeleton was made with just one print without any pieces fusing together.

Making something with 3D printer is pretty straightforward once you do it a few times. The first step is find out what you want to make and then figure out if 3D printing is the best way to produce the thing that you want to make (The old saying: if you have a hammer, everything looks like a nail). For this article I decided to make a shift knob. Will my time, material costs, and wear and tear costs be less than what it would cost to purchase a similar shift knob? Yes. Should the construction of the part hold up to the operating conditions? Yes. Okay, lets make a 3D printed shift knob.

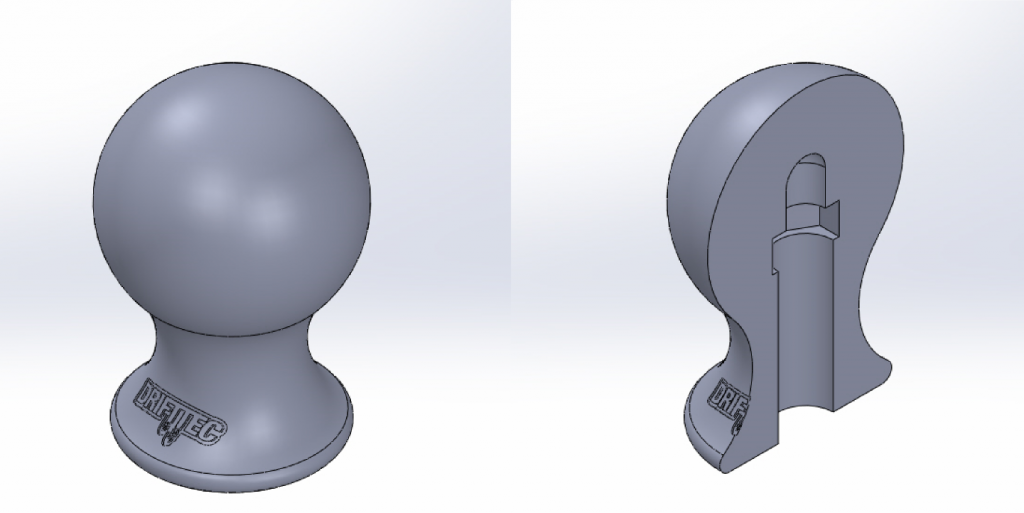

Now we have to either make a solid model of the part we want to make or we have to find it somewhere. Here is a great place to find already made files ready to print. Now I wanted the DriftTec logo in my shift knob so I decided to design my own shift knob. I took dimensions from the shifter assembly in the car to design my part. I also designed provisions for a nut to be inserted into the middle of the part.

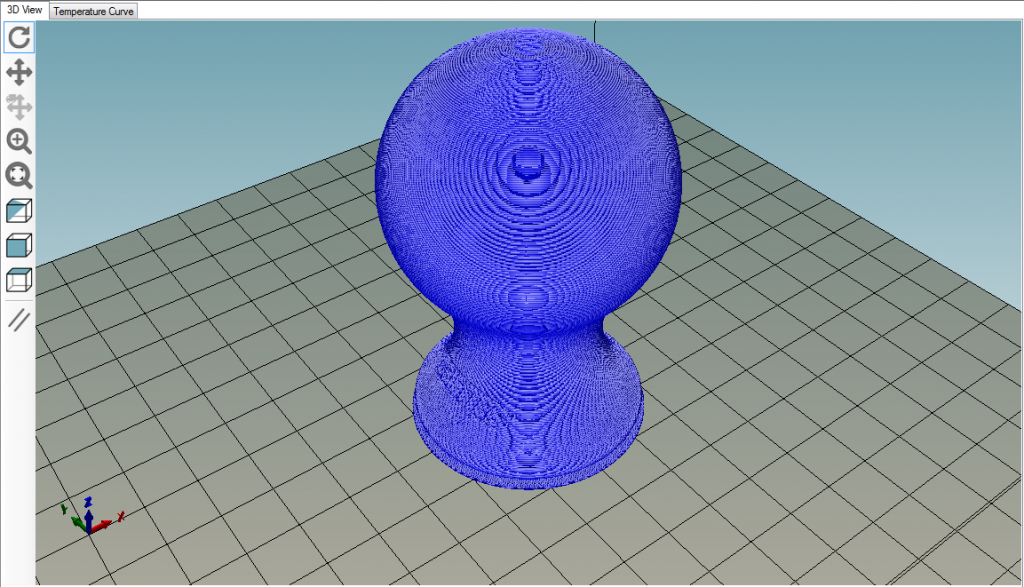

Once the .stl file is produced it is then sent to the slicing software. This software converts a solid model into layer by layer instructions that the 3D printer can understand (g-code, just like a CNC mill). This step is really important. This is where you can adjust almost anything about how the part will be printed (print speeds, layer height, support structure, etc.). It does take some time and plenty of tinkering to get all the settings dialed in and even then there is constant fine tuning needed from print to print.

I had the slicing software instruct the printer to stop printing right after the hex section was finished printing. This allowed me to embed a nut into the print that would allow the shift knob to thread onto the shifter assembly like any other shift knob. This also spreads out the loads from shifting to a larger surface area on the plastic which decreases the localized stresses within the plastic part of the shift knob.

From there the print was finished as normal. As a last touch, paint was applied to the ridges created by the DriftTec logo in the base of the shift knob.

Easy as that, it took less than an hour of my time measuring, modeling, and post processing to create this functional part. While the part was printing I could do other things (although you can get mesmerized by watching the printer sometimes).

3D printing is a great way to get parts made in hours rather than receiving them in days or weeks!

-Mark